Cost effective Corn Puffed Extruder Machine Snacks Extrusion Line Food Expander

Product Description:

Corn Puffed Extruder Machine Snacks Extrusion Line Food Expander adopts wheat flour, rice ,corn flour etc as the raw meterial to produce all kinds of puffed snack food .

From mixing to the final products, just require 2-3 people to operate the whole line. Besides, Puffed cassava snack machine extruded tapioca food extruder puffing machinery can produce different shapes of puffed snacks food by changing the dies.

Description of Machinery

Raw Material Mixer

Input Conveyor for Extruder

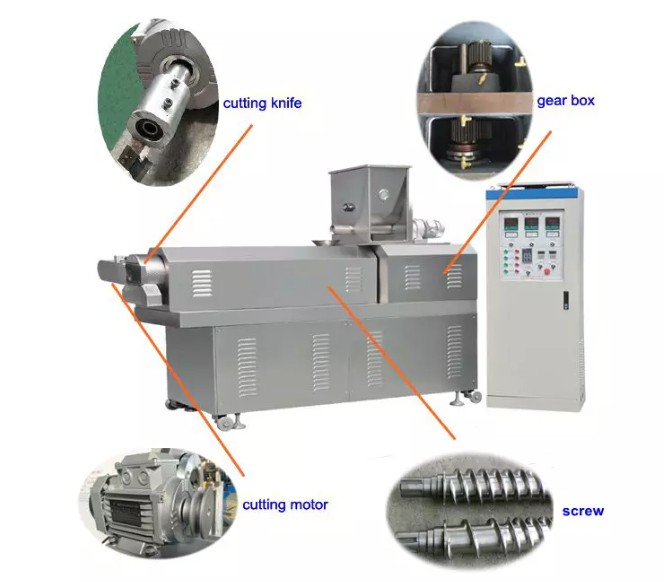

Grain Puff extrusion machine (main production machine)

Input Conveyor for Drying or Roasting

Drying or Roasting Section

Seasoning Section with Flavor Applicator

Output Conveyor for Seasoning

Packing Section (Auto Vertical Packing - Pillow Pack)

Description of Manufacturing Process

In the mixer the raw materials are mixed and brought to the desired moisture level. The mix is then transferred to the extruder hopper; a level indicator ensures that the extruder does not run empty. In the extruder the raw materials are pressed through a die using high-pressure build-up by the screw and high temperature created by shear between sleeve and screw.

The pressure drop at the die causes the snack to expand and the face cutters set the desired snack length and mass. After extrusion the snacks are baked for extra crispness and for shelf-life.

They are then coated with palm oil, and then with flavor powder.

Coating takes place in the rotating coating drum. Now the snacks are ready to be packed; this is best done immediately. It is recommended that a buffer silo is installed between packing equipment and processing line, mainly to overcome the differences in operational speed.

Direct extrusion is the process whereby grits (of i.e. corn) is forced through a die into the final snack-shape, and flavorings are added to produce a tasty snack. Grain Puff Snack Food is a very good snack food to enter into a new market because its raw material is low cost and it can have many different looks which refresh consumers’ mind easily.

Our Services

Pre-sale service:

24 hours online service .

Configue the machines as your output or request.

In sale service:

Strictly supervise the manufature of the machines

Convey the manufature information to you in time.

After sale service:

1 year warranty for the machines.

Overseas installation and train the first-line operators.

For any questions, professional technicians will solve for you timely.

replacement Pump of Corn snack expander data list | ||||||||

|---|---|---|---|---|---|---|---|---|

| No. | D | d | B | Weight | C | Inventory | Minimum Buy Quantity | |

| HR30307DJ | 80 mm | 35 mm | 21 mm | 0,519 Kg | 62 kN | - | - | |

| 23220CJ | 180 mm | 100 mm | 60,3 mm | - | 60,3 mm | - | - | |

| 7014 CD/HCP4A | 110 mm | 70 mm | 20 mm | - | - | - | - | |

| 7209HG1DUJ74 | 85 mm | 45 mm | 38 mm | - | 38 mm | - | - | |

| 4 15/16 SLV RTL EXP PB | - | - | - | 192.95 | - | 0.0 | N/A | |

| QAPL11A055SEC | 3.125 Inch | 79.38 Millimeter | 2.165 Inch | 55 Millimeter | 2.5 Inch | 63.5 Millimeter | 6.356 | - | 0.0 | N/A | |

| 7301BEAT85SUN | 1.457 Inch | 37 Millimeter | 0.472 Inch | 12 Millimeter | 0.472 Inch | 12 Millimeter | 0.056 | - | 0.0 | N/A | |

| GRLP207-23 | - | - | - | 0 | - | 0.0 | N/A | |

| SAFD056K/10 | - | - | - | 0 | - | 0.0 | N/A | |

| B954C016024 | 3 in | 2 in | - | - | - | - | - | |

| 2209e-2rs1ktn9-qbl | 85mm | 45mm | 23mm | - | - | - | - | |

| 6310 | 110 mm | 50 mm | 27 mm | - | 27 mm | - | - | |

replacement Pump of Corn snack expander data list | ||||||||

|---|---|---|---|---|---|---|---|---|

| No. | Inventory | Weight | Minimum Buy Quantity | d | B | D | EAN | |

| E-5244-UMR | 0.0 | 77.725 | N/A | 8.661 Inch | 220 Millimeter | 5.25 Inch | 133.35 Millimeter | 15.748 Inch | 400 Millimeter | 0637410021969 | |

| MS10 | 0.0 | 0.681 | N/A | - | - | - | 0781711334461 | |

| 22317 | 0.0 | 7.44 | N/A | 3.346 Inch | 85 Millimeter | 2.362 Inch | 60 Millimeter | 7.087 Inch | 180 Millimeter | 0644075165891 | |

| GE-75 SW | 0.0 | 1.102 | N/A | - | - | - | - | |

| CFES12-1B | 0.0 | 0.11 | N/A | - | - | - | 4549557012372 | |

| 6311P5 | 0.0 | 1.37 | N/A | 2.165 Inch | 55 Millimeter | 1.142 Inch | 29 Millimeter | 4.724 Inch | 120 Millimeter | 0029176099793 | |

| TA170XB83964 | 0.0 | 8.45 | N/A | - | - | - | - | |

| F-684AX50 | - | - | - | 4 | 2.5 | 9 | - | |

| 7015acyu/glp4-nachi | - | - | - | 75mm | 20mm | 115mm | - | |

| 6908L11-H-20DDU | - | - | - | 40 mm | 12 mm | 62 mm | - | |

Customer Cases For Corn snack expander For Factory In 2022 | |

|---|---|

| 1 | High Quality Expanded Snack Machine Process In Malaysia |

| 2 | Small Corn Puffed Extruder Snack Machine Expand Corn Snacks Food Machinery Production Line Price For Sale Argentina |

| 3 | High Quality Expanded Snack Machine Process In Turkey |

| 4 | Stainless Steel Rice Corn Expanding Machine/Cereal Puffing Machine/Corn Snacks Popping Puffing Machine Process In Sri Lanka |

| 5 | Expand Corn Snacks Food Extruder Expanded Snacks Processing Machine Food Extrusion Machine Process In Sri Lanka |

| 6 | 30-50 kg/h Puff snacks Production Plant Corn Cheetos Puff Snacks Food Extruder Machine For Sale Sri Lanka |

Customer Cases For Corn snack expander For Factory In 2022 | |

|---|---|

| 1 | Corn Puffs extruded Extruder Snack Machine Expand Corn Snacks Food Machinery Production Line Price Process In Sri Lanka |

| 2 | Small Corn puffed Extruder Snack Machine Expand Corn Snacks Food Machinery Production Line Price Process In Sri Lanka |

| 3 | Double Screw Snack Extrusion Machine To Make Corn Puff Chips Expander For Sale Argentina |

| 4 | Crisp fruit machine puffing rice and corn/ Bend pipe extrusion machine (skype:wendyzf1) Sale In Zimbabwe |

| 5 | Snack Food Production Line / Puff Snack Food Machine /Corn Snack Food Processing machine Process In Singapore |

| 6 | Expand Corn Snacks Snack Corn Snack Extruder Direct Expand Corn Snacks Food Making Machine Diesel Engine Crunchy Corn Puff Snack Food Bulking Extruder Process In Malaysia |

| 7 | Snack Food Expanding Machine Puff Snack Food Making Machine Corn SnackExtruder Process In Malaysia |

| 8 | Double Screw Snack Extrusion Machine To Make Corn Puff Chips Expander Process In Ethiopia |

Corn snack expander Project Price List | |||

|---|---|---|---|

| Product | Quantity | Min Price ($) | Max Price ($) |

| Double Screw Snack Extrusion Machine To Make Corn Puff Chips Expander | 1 Set | US$1509 | US$5922 |

| Cereal Bar Snack Food Making Machine High Quality snack Expander | 1 Set | US$1840 | US$5921 |

| Inflated cereals snacks machines expand cereal corn flaks making machine | 1 Set | US$1084 | US$5944 |

| Energy saving corn puffed expanded snacks food making machine | 1 Set | US$1485 | US$6978 |

| The High Efficiency Grain / Rice / Corn Expander | 1 Set | US$1705 | US$6191 |

| Small Puffed Corn Starch Expander/Extruded Cereal Flour Bulking Machine/Maize Corn Flakes Extruding Machine for Crisp Snack | 1 Set | US$1176 | US$6981 |

| Corn Puffed Expanded Snacks Food Making Machine industrial machines manufacturer | 1 Set | US$1434 | US$5696 |

| Industrial Corn Puffed Expanded Snacks Food Making Machine | 1 Set | US$1903 | US$6674 |

| High Quality Multifunctional Cereal Expander Cheese Honey Corn Puff Snacks Extruder Machine Production Line Equipment Twin Screw Extruder | 1 Set | US$1333 | US$5921 |

Copyright © 2017 - 2025Jinan TUOBO Microwave Machinery Co.,Ltd. All Rights Reserved